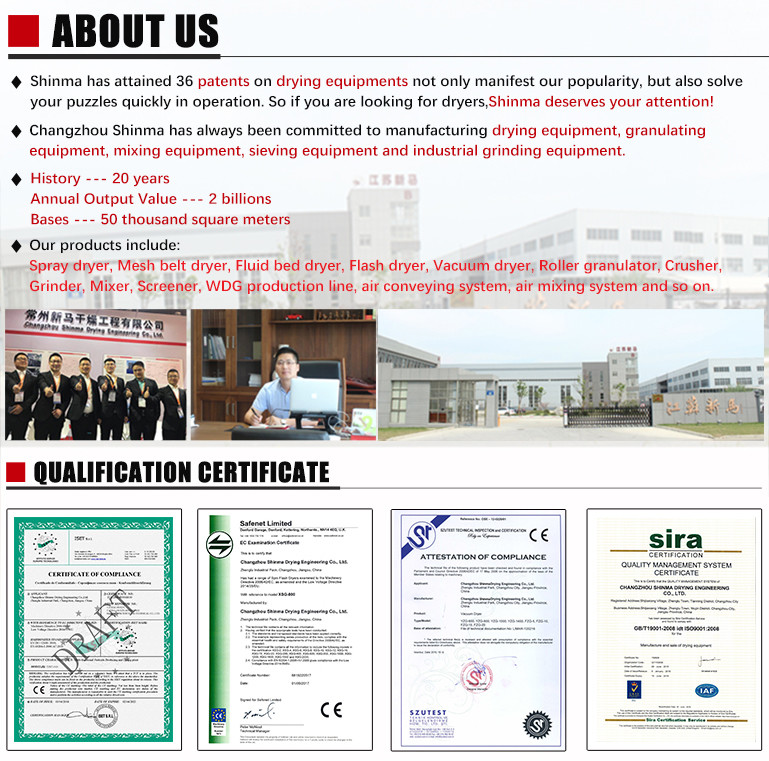

Changzhou Shinma Drying Engineering Co.,LTD, in jintan

district,changzhou city of Jiangsu, which is in the middle of

Shanghai-Nanjing Express way. Company has 2 large modern

construction machinery manufacturing plants, equipped with whole

line of sheet metal bending, laser cutting, automatic polishing,

automatic welding, occupies an area of 500,000 square meters. Also

we have our own R&D team, which has a number of talents and

individual test lab.

We are specializing in researching and developing drying machine,

such as spray dryer, mesh belt dryer, fluid bed dryer, flash dryer,

air stream dryer, vacuum dryer, plate dryer and so on. As auxiliary

machines of drying machine, we also supply mixer, granulator,

grinder and screener, roller compactor, air flow mixing system and

air flow conveyor. With rich experience, we keep leading in design

and manufacturing Chinese herbal extract spray dryer, flavouring

spray dryer, hydrolyzed protein spray dryer, desiccated coconut

drying machine, coconut meat mesh belt dryer, pharmaceutical spray

dryer, vegetable and fruit dehydrator (mesh belt dryer), bread

crumb fluid bed dryer, enzyme spray dryer, chicken powder

production line, seaweeds drying processing line, gelatin

production, WDG production line and so on.

Based on keep stable quality of drying, mixing, granulating,

crushing and sieving machines, we actively research and develop new

product, like roller compactor, airflow conveying and mixing

system, try to supply turnkey projects to our customers.

On many years of research and production experience, we have

absorbed a wide range of latest technology in drying technologies.

Products are sold well all over the country and exported to

Southeast Asia, Brazil, Türkiye, Australia, and other countries and

regions.We always insist on win-win cooperation, and we are deeply

trust in "One for all, all for one!"